Full Automated Hydrographic Survey Solution——How HydroFrog 25 USV works with NORBIT and Caris Onboard

2025-07-06

HydroFrog 25 as a Survey Platform

This year marks the third year since the official launch of HydroFrog 25. Users who have been following us will notice that we have published multiple case studies showcasing the collaborative operations of the HydroFrog 25 USV with multibeam sonar and subbottom profiler.

From the early stages of its founding, OceanPhysics had a slightly different concept from other companies specialising in USVs. As most of the founding team members had more than ten years of experience in underwater surveys, in addition to ensuring smooth vessel control, we focused more on how to make it a more professional and user-friendly underwater survey platform.

For example:

• New Design of the Catamaran

• Narrow and long vessel design: improve propulsion efficiency, increase speed, better straight line retention, help marine survey line work;

• Catamaran structure design: smooth sailing, enhanced stability of rolling, closing convergence to enhance pitch stability, can operate in class 3 sea state;

• Large space: 2.5m X 1.25m X 0.7m, can carry all kinds of sensors.

• EPP Material for the hull

• Special polymer materials: environmental protection, shock absorption, heat insulation, flame retardant, impact resistance and other characteristics, low production costs;

• Multi-watertight cabin design: water ingress in part of the cabin does not affect the ship's navigation, and the USV will not sink even that all the cabins are damaged, so as to guarantee the safety of the instruments and equipments;

• Lightweight: the empty vessel weighs 25kg (excluding battery) and can carry 45kg, leaving enough space for the load.

• Strong Battery and Propulsion

• Large-capacity waterproof battery: 114Ah, 37V lithium battery, IP67 waterproof, puncture and extrusion resistant, at economic speed: 5 hours of endurance;

• High-power electric propulsion: 2 X 2.5 kW electric propulsion, effective speed: 4-5 knots, maximum speed: 10 knots, efficient and reliable, forward and reverse plus infinitely variable speed can be turned around in place, less than 400 watts of propulsion power is needed at 4 knots of airspeed, easy to remove and replace with 4 fixing bolts.

• Special Designed Truss and Lifting Fins

• Carbon Fiber truss: high strength carbon fibre structure, 1/2 the weight of aluminum, 1/4 the weight of stainless steel, but strong enough to withstand 80kg. 0.6 square meters of the truss end remains after installation of the equipment bay, making it easy to carry a wide range of mission equipment;

• Wet end lifting fins: 60/110cm options; optional lifting fins specially designed for small multibeam, carbon fibre structure, high rigidity, no gap, corrosion resistance. There are two types of lifting: manual and automatic (optional).IMU, antenna, and multibeam are mounted on a single structure to avoid relative position changes after disassembly.

• Automatic Profiling Winch (Optional)

• Maximum cable length: 120m;Maximum 0.5m/s spooling;Support web browser, remote control;Payload 10kg; Size: 13 x 11 x 11 cm, Weight: 1.85kg

Field Test with NORBIT

When we talk about USVs, the ‘U’ stands for “unmanned” or “uncrewed”, meaning that no one is on board to operate the vessel; instead, it is remotely controlled from shore. In actual underwater surveying operations, we often find that there are still many tasks that require human intervention, such as pre-setting navigation routes, adjusting and configuring multibeam parameters, and conducting real-time data quality control.

On 6 June 2025, following several rounds of technical discussions, we commenced our first joint testing with NORBIT. NORBIT is an experienced manufacturer of multibeam sonar systems and has gained widespread recognition from Chinese users.We have always been highly interested in their DCT(Data Collection Tool) system. By using DCT, multibeam sonar can be seamlessly integrated with USVs, and with Autopilot, survey lines can be automatically planned based on seabed coverage, enabling intelligent start/stop data recording. As a result, USVs are now truly transformed into Autonomous Surface Vehicles (ASVs).

DCT

The Data Collection Tool (DCT) - is a survey data acquisition utility, part of NORBIT’s offerings aimed to simplify the standard bathymetry survey operations. The general bathymetry grid is displayed in a web browser allowing quick estimation of the coverage and data quality in real-time while running the survey.

DCT can be operated with a simple touch screen of the navigation plotter, tablet, smartphone or PC by a single person. By reducing the amount of configuration required by the user the real-estate on the screen is maximized allowing for a clear, precise and easy way to understand the interface. With a simple Start/Stop button the user can acquire the needed data which are then recorded on the survey PC. The skipper or boat driver can run the survey without constantly reconfiguring the system, allowing him to concentrate the efforts on safety aspects and any other tasks while running the survey operation. In cases where help from a more experienced surveyor is needed, the displays can be accessed from anywhere in the world (e.g. via VPN over 4G access) and from any terminal equipped with a web browser.

With a tap of a finger or by a mouse click users can draw lines, generate a number of wing lines with given spacing in just seconds. Each line can be adjusted, moved, rotated, resized or deleted as needed. The mission planning can be performed in the office or on the boat. Then the survey scheme can be saved as a disk file and emailed or shared with another PC to be loaded on the sur-vey setup. That allows for mission planning in advance and sharing of the survey plans with other team members. The mission planning can be supervised from the office as long as there is net-work access (e.g. via VPN over 4G) to the boat and simply navigating with the web browser to the survey PC. Then the mission planning can be shared and modified as needed.

NORBIT WINGHEAD i77h

The multibeam sonar used was the NORBIT WINGHEAD i77h—the market’s first cylindrical, ultra-high-resolution broadband bathymetry sonar. Its lightweight and compact design make it an excellent choice for USV integration.

WINGHEAD i77h Key Features:

• Beam Width: 0.5° × 0.9° at 400 kHz

• HD Beamformer: 1024 beams per ping

• Integrated GNSS/INS: Applanix OceanMaster

• Built-in Sound Velocity Probe

• Low Power Consumption

• Compact Design for Rapid Deployment

• Optional LiDAR Integration

Thanks to its industry-leading curved array technology, the WINGHEAD i77h offers exceptional IHO compliant swath coverage exceeding 140°, while maintaining minimal resolution loss. During the demonstration, the sonar achieved an impressive 150°–160° swath angle in equidistant mode—resulting in 9–10 times water depth coverage, achievable only through curved array design or traditional Flat array sonar at Dual-Head mode.

CARIS Onboard

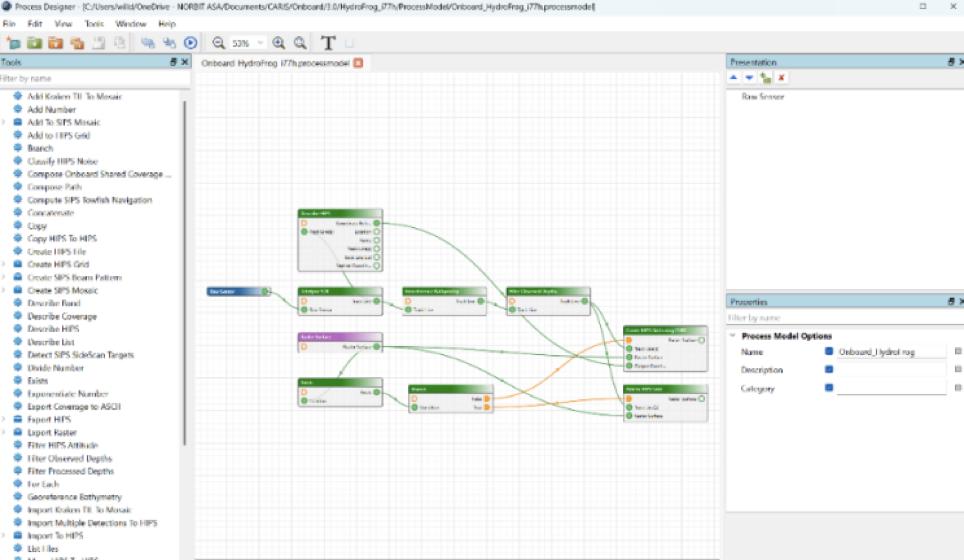

The CARIS Onboard software was also integrated as part of the system. As the most widely adopted solution for bathymetric data processing, CARIS HIPS & SIPS has long set industry standards. With the evolution of computing technology, CARIS Onboard was introduced to move traditional post-processing workflows into a real-time, onboard pre-processing environment. Users can now automate workflows such as:

• Creating HIPS project with predefined vessel file

• Georeferencing bathymetry with Sound Velocity Correction and Tide Reduction (or GPS Tide)

• Generating CUBE surface

• Performing AI noise cleaning

• Exporting to XYZ points

As a result, once the survey mission concludes, a fully processed, production-ready bathymetric dataset is immediately available.

Both NORBIT DCT and CARIS Onboard are browser-based applications, allowing project managers or administrators to remotely monitor and manage the entire survey via mobile devices or tablets.

Conclusion

In this test, we successfully achieved seamless integration of hardware and software:

On the hardware side, from stable all-in-one installation to autopilot survey operations, the HydroFrog 25 performed reliably even under high temperatures of 35°C on the day of the test.

On the software side, we utilised DCT for automatic mission planning, multi-beam control, and data acquisition; NORBIT's OHP platform enabled real-time sound velocity/tide correction and point cloud direct output, achieving ‘measurement as results’ when quality control standards were met; and Caris Onboard facilitated online data post-processing, allowing data reports to be viewed immediately upon completion of the survey task.

This truly achieves high-quality, high-efficiency, and high-safety fully automated underwater surveys!